Casing oscillators play a critical role in ensuring the stability and accuracy of casing installations in pile drilling projects. Despite their extensive use, many engineers are still unfamiliar with the intricate working principles, key functions, and unique features of casing oscillators. This article aims to provide a comprehensive overview of it.

What are Casing Oscillators?

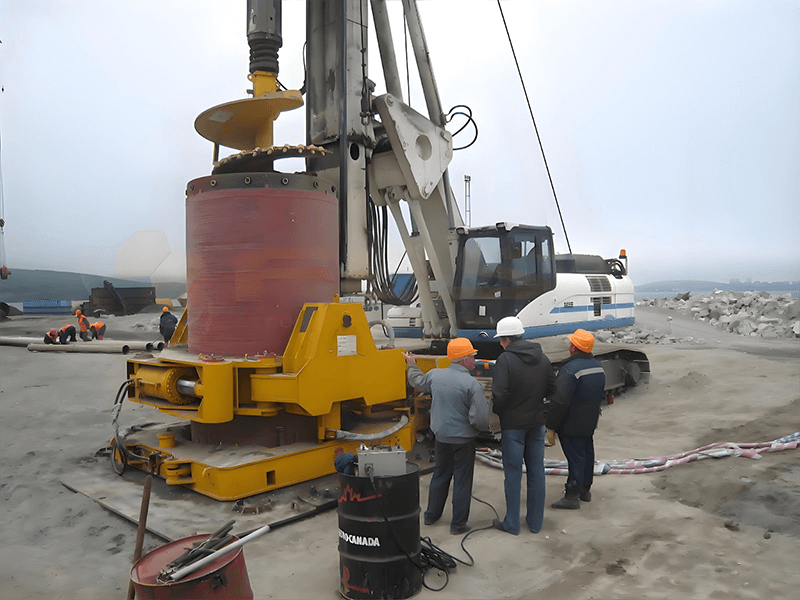

Casing oscillators are crucial in pile drilling, especially when dealing with unstable strata conditions. In such scenarios, the all casing method is employed, requiring the casing to be driven to its full depth to prevent the hole from collapsing. To facilitate this process and ensure optimal performance, a casing oscillator is strongly recommended.

These machines excel with their superior oscillating torque and lifting force, making them highly effective at driving and retracting casings. Instead of using hammering or vibration, casing oscillators utilize rotational force to insert the casing into the ground, ensuring precise placement even in the toughest terrains. Casing oscillators not only improve efficiency but also ensure the structural integrity of the drilled hole, making them indispensable in modern construction projects.

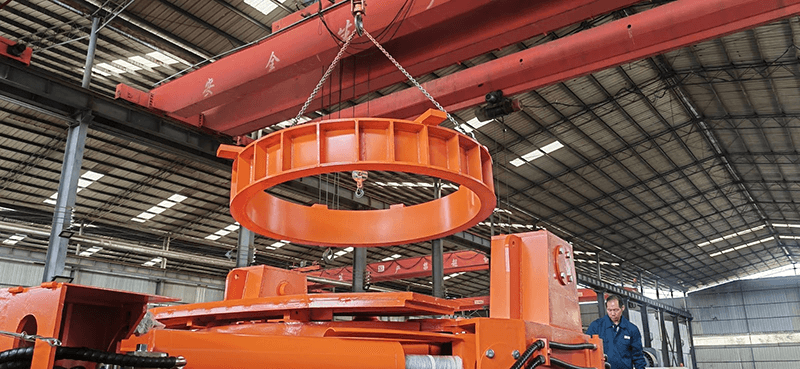

How to Adapt a Casing Oscillator for Different Sizes of Casing?

The diameter can be easily adjusted by adding inserts, allowing for seamless adaptability to various casing sizes, with options available up to 3000mm. By using an exchangeable reducer adapter, the oscillator can be quickly converted to handle smaller casing diameters. This flexibility is achieved through the installation of a reducing adapter, enabling the application of casing sizes smaller than the specified diameter of the casing oscillator. This adaptability ensures that the casing oscillator can meet the diverse requirements of any drilling project, providing both efficiency and precision.

Here is the specification of FES casing oscillator

|

Spec. |

Unit |

FGJ1200S |

FGJ1500S |

FGJ2000S |

FGJ2800S |

|

Casing diameter |

mm |

600~1200 |

800~1500 |

1000~2000 |

1800~2800 |

|

Torque |

kN.m |

1200 |

1900 |

2860 |

6500 |

|

Stroke |

mm |

450 |

450 |

450 |

650 |

|

Lifting force |

kN |

1560 |

1880 |

2280 |

7500 |

|

Clamping force |

mm |

1500 |

1800 |

2200 |

\ |

|

Overall size(L*W*H) |

m |

4.2*2.4*1.7 |

4.28*2.5*1.75 |

4.9*3.1*1.8 |

9*4.5*2.5 |

|

Weight |

kg |

16000 |

18000 |

23000 |

48000-50000 |

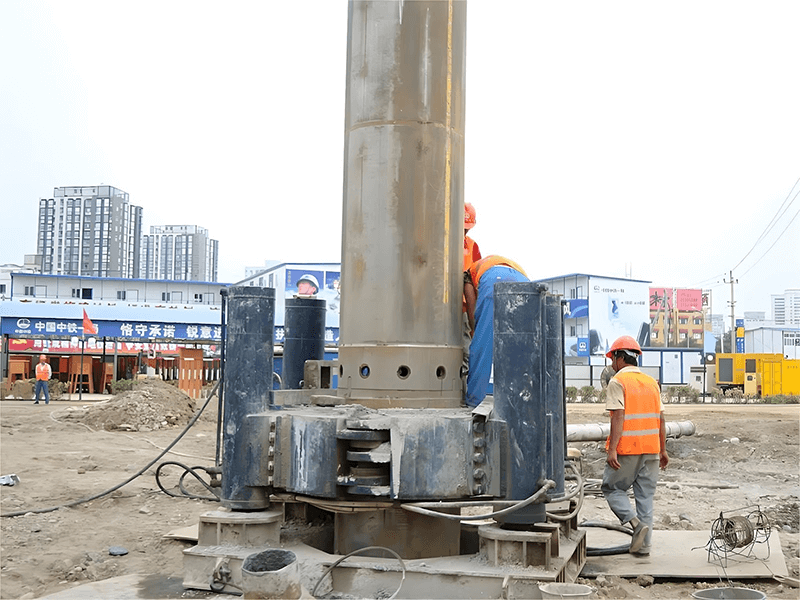

Casing Oscillators Can be Operating Remotely

Experience the convenience and safety of operating casing oscillators remotely, significantly reducing the need for manual intervention. This remote control functionality allows operators to manage the equipment from a safe distance, enhancing efficiency and ensuring precise control over the oscillating process. By minimizing direct contact, remote operation also increases safety on the job site, making it an invaluable feature for modern construction projects.

High-Quality Valves and Powerful Performance in Casing Oscillators

High-Quality Valve: Our casing oscillators are equipped with high-quality Rexroth valves, which ensure reliable and precise control over the entire operation. These valves are known for their durability and efficiency, providing consistent performance even under challenging conditions.

Powerful Performance: The oscillators are powered by a robust processing cylinder that delivers exceptional strength and efficiency. This powerful performance ensures that the equipment can handle demanding tasks with ease, maintaining high productivity and minimizing downtime.

High Strength Welding Process: The design and construction of our casing oscillators are founded on FES’s over 20 years of specialized experience in pile foundations. Recognizing the significant costs associated with equipment breakdowns on-site, we have emphasized the importance of exceptional strength and durability in our construction process. Our high-strength welding techniques enhance the structural integrity of the oscillators, ensuring they withstand rigorous use and deliver reliable performance throughout their service life.

What is the Process of Casing Oscillator Method in Bored Pile Construction?

- Site Preparation: Level and clear the construction site of any obstructions.

- Positioning the Casing: Place the casing at the desired location and attach the casing oscillator to the top.

- Driving the Casing: Use the casing oscillator's rotational force to drive the casing into the ground.

- Drilling and Removing Spoil Material: Begin excavation inside the casing using a drill rig or grab bucket, removing spoil material to create a clean hole.

- Reinforcement Placement: Lower the reinforcement cage into the drilled hole.

- Concreting: Pour concrete through the sectional tremie pipe.