Super Large Diameter, Super Challenging Construction! “World’s Top Drill” XR1600E Sets a Record with its Inaugural Pile!

The remarkable achievement of XR1600E, known as the “World’s Top Drill,” has been revealed: with a diameter of 6.3m|20.7 ft, a pile depth of 106m|348ft, and a rock penetration of 40m|131 ft, it establishes a world record in pile foundation construction.

The larger the span of a bridge, the sturdier the bridge piers must be to bear the load. And XCMG XR1600E rotary drilling rig participated in the construction of the Xihengmen Bridge. This project is a shared cross-sea bridge for the Ningbo-Zhoushan Railway and Ningbo-Zhoushan Expressway, spanning the Xihengmen Channel. With a main span of 1488m|4,888 ft, it is currently the world’s largest cable-stayed and suspension hybrid bridge under construction, and also the largest dual-purpose railway and highway bridge in China. For the foundation of Pier 5, 18 cast-in-place piles of 6.3m|20.7 ft in diameter are used for load-bearing. Under complex marine conditions of strong winds, swift currents, exposed bedrock, and deep waters, the XR1600E rotary drilling rig undertakes the foundational work for this super-long-span sea-crossing bridge, accomplishing the largest 6.3m|20.7 ft diameter drilling work currently undertaken in the country!

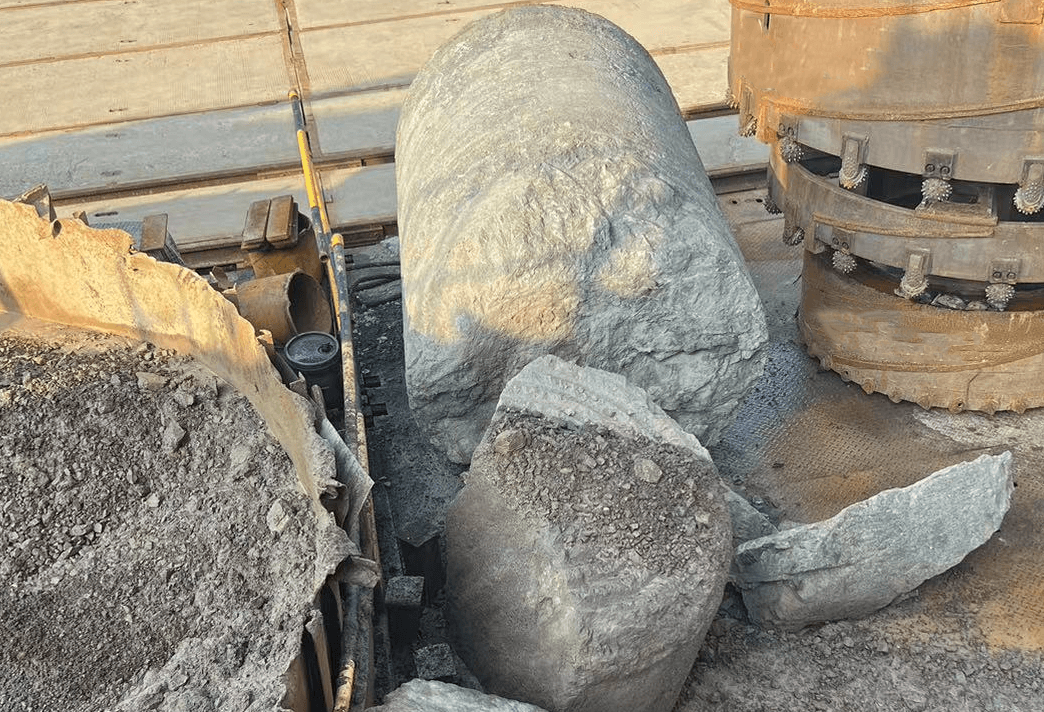

The construction site is located in an area with extremely hard rocks! Powerful sea winds drive surging waves day and night, washing away loose rock layers on the seabed. By observing the enormous rocks extending from the seabed, one can imagine the topography and structure of the seabed, where the hardness of the underwater rocks reaches up to 100 megapascals, with a rock penetration depth of 40m|131 ft.

Drilling in such a place is tantamount to challenging nature, especially when dealing with large-diameter 6.3m|20.7 ft borehole piles. This marks the largest borehole pile foundation construction in the country, raising the construction difficulty and technical complexity to a whole new level. This also means that every inch XR1600E rotary drilling rig drills downward is met with unforeseeable and unimaginably complex situations.

Facing these difficulties, the bridge builders have come up with many ingenious solutions, including employing the high-performance XCMG XR1600E for construction operations. This equipment relies on multiple intelligent technologies, such as the dual-power system, super-large lifting force single-row rope hoist, multi-gear mode rotary head, and visualized drill rod, fearlessly conquering construction in deep waters and hard rocks. It breaks away from the conventional step-by-step drilling process, reduces the number of steps, and takes the lead in adopting the four-step drilling process of 2m|6.5ft, 3m|9.8ft, 4.5m|15ft, and 6.3m|20.6ft, smoothly traversing complex geological formations like strongly weathered granite, weakly weathered fractured granite, fragmented rock, and slightly weathered fractured rhyolite.

Ultimately, XR1600E rotary drilling rig successfully surpasses the industry’s 1.8m|5.9ft drilling expansion limit, shattering the world record in pile foundation construction with a 6.3m|20.7 ft borehole diameter, 40m|131 ft rock penetration depth, and a total depth of 106m|348ft.

Post time:Aug-01-2023